EQUIPMENT LTD

Nos

Réalisations

Convoyeur horizontal

Convoyeur incliné

Convoyeur vertical

Convoyeur niveleur

Vanne guillotine

Chute bidirectionnelle

Trémie avec vis d'extraction

Trémie de stockage

Trémie mobile

Entreposage souterrain

Dessableur

Classificateur à sable

Réservoir de sédimentation

Dégrilleur à vis

Laveur-compacteur

Presse à vis

Dosage de poudre

Extracteur de silo

Stand de vidande de super-sac

Trémie vide-sac

Live with soul

Horizontal conveyor

Inclined conveyor

Leveling conveyor

Screw feeder

Compactors

Flat bottom silo extractor

Paddle mixer

Spare parts and accessories

Screw without soul

Screw with core / Reloading

Wear coatings

Geared motor

Drive shaft

Cable glands and special seals

Intermediate bearing / bearing

Outsoles

Flexible fall

Cracked sieve

Spiral brush

Emergency stop cable

Rotation detector

Circuit breaker

Local control panels - Control (PLC / HMI)

Level sensor / Weighbridge / Instrumentation

Lime preparation tank

Pump skid

Silos

Hoppers

Screw without soul

Horizontal Conveyor

Fully sealed to limit odours and leaks, they are designed to transport more than 60 m³/hour of sticky, slimy, stringy materials and all types of materials likely to clog and/or form keystones.

Up to 45 meters in length for a single conveyor, the absence of ball bearings at the end allows direct connections when the path of the materials transported requires several conveyors in series, whether horizontal, inclined or vertical.

The maintenance of these conveyors is very simple and their use is particularly economical.

CASE STUDY: SCREENING DISCHARGE CONVEYOR

A screening reject conveyor receives the rejects from two screens. The conveyor transports the rejects to a washer-compactor. The washer-compactor filters the organic matter and then compacts and spins the rejects.

Conveyor capacity: 4 m³/h of discharge

Trough filling rate: 37%

Screw rotation speed: 15 rpm

Safety devices: 1 rotation detector, 1 emergency stop cable, 1 circuit breaker.

Inclined Conveyor

Inclined coreless screw conveyors are used to transport materials at up to 45° inclination.

CASE STUDY: INCLINED CONVEYOR FOR CENTRIFUGAL SLUDGE

The inclined conveyor receives the sludge from a centrifuge, transports it and raises it to transfer it to an elevated conveyor intended to load a truck by 4 outlet chutes. 3 outlet chutes are equipped with guillotine valves allowing uniform filling of the truck bin located under the unloading conveyor

Conveyor capacity: 10.19 m3/h

Trough filling rate: 50%

Screw rotation speed: 20 rpm

Conveyor inclination angle: 40°

The gear motor is installed at the top of the inclined conveyor while a 6-inch drain is welded onto the bottom end plate of the conveyor.

Safety device: 1 rotation detector, 1 circuit breaker

Vertical conveyor

Vertical coreless screw conveyors are used to transport materials that cannot be pumped. Atara™ is proud to have installed in 2002 the highest vertical conveyor in the world for the extraction of 10 m3/hour of sand and vertical transport over 21 meters. This installation is still in operation.

CASE STUDY: VERTICAL CONVEYOR FOR CENTRIFUGAL SLUDGE

The vertical conveyor receives the sludge from a centrifuge, which it transports vertically to transfer it axially into a recovery conveyor. The recovery conveyor then transfers the sludge into a horizontal truck loading conveyor via two outlet chutes equipped with guillotine valves. The loading conveyor is designed to load a truck via 4 outlet chutes. 3 outlet chutes are equipped with guillotine valves allowing uniform filling of the truck bin located under the loading conveyor, the last chute being open at all times.

This system includes 4 horizontal conveyors and one vertical conveyor

Conveyor capacity: 4.7 m3/h

Vertical trough filling rate: 100%

Screw rotation speed: 15 to 20 revolutions/minute

Safety device: 5 rotation detectors, 4 emergency stop cables, 5 circuit breakers

Leveling conveyor

Installed above skips, hoppers or truck trailers, they optimize their filling with or without guillotine valves.

CASE STUDY: TRUCK LOADING

This unloading system consists of a cross conveyor feeding two unloading conveyors.

The cross conveyor receives by gravity the sludge from two centrifuges operating on the upper floor. It then transfers the sludge to one or the other of the discharge conveyors. These two conveyors discharge the sludge through their five outlet chutes, four of which are equipped with guillotine valves.

Level sensors are designed to detect the presence of a trailer. When the presence of a trailer is detected, the sensors send a signal to start loading the slurry. Once the sensor of the last chute detects that the pre-set maximum loading level has been reached, a new signal stops the system or transfers the excess slurry to the other conveyor. The full trailer can be replaced by a new empty one.

· Conveyor capacity: 12m³/h

· Trough filling rate: 45%

· Screw rotation speed: 21 - 23 rpm

Safety devices: 3 rotation detectors, 3 circuit breakers and 10 level sensors

Guillotine valve

With their ultra-robust design, Atara™ knife gate valves combine simplicity and efficiency. 100% leak-proof when the application requires it, the Atara™ knife gate valve range combines perfectly with all types of screw conveyors, both for conveyors manufactured by Atara™ and by others. They can be operated manually, pneumatically or electrically.

Two-way fall

Atara™ designs bi-directional chutes that allow material to be directed alternately into multiple conveyors. They can be operated manually, pneumatically or electrically.

Frequently used to redirect product from one (1) piece of equipment to another (1) piece of equipment (as shown in the photo). The diverter chute is also used to divert material from one chute to another.))

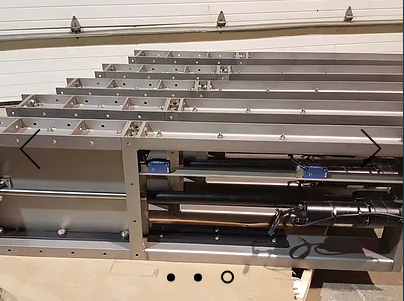

In the photo below we can see two (2) coreless screw conveyors located below the infeed chute, the switch chute is located in the center of the chute, the bottom of the switch chute is secured to support the end of the chute, allowing the blade to pivot on the outer end. The position of the blade allows the material to be guided into the selected conveyor below.

The blade function can be operated by an electric or pneumatic actuator.

Hopper with Extraction Screw

Whether made of steel or stainless steel, the bottom of Atara Equipment Ltd hoppers is equipped with a series of coreless screws that allow 100% emptying. Their dimensions can vary from less than one cubic meter to several hundred cubic meters.

Hoppers with extraction screws may only have one (1) or more screws at the bottom of the hopper.

The storage hopper can be made in different shapes; round, square or in the case of this photo, the hopper is rectangular equipped with twin extraction screws. The hopper capacity is 100m³.

The storage hopper sits on four (4) scales, the scales monitor the amount of sludge being discharged into the trailers and the amount of sludge still in the hopper. The sludge exits the hopper through six (6) gate valves. Each discharge chute has a motion sensor.

The motion sensor controls the storage height in the trailer by sending signals to open and close the appropriate slide valves. Once the pre-set maximum height is reached and the weight of the mud in the trailer is correct, the transporter can remove the trailer.